Land Rover Defender: Component Location, Overview

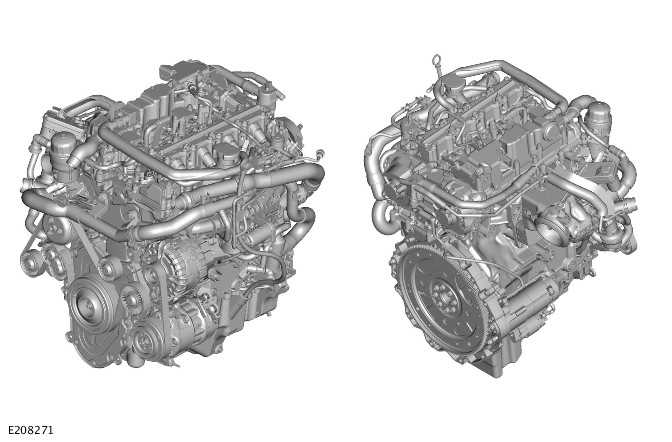

COMPONENT LOCATION

COMPONENT LOCATION - EXTERNAL VIEW

OVERVIEW

The Ingenium I4 2.0L petrol engine is an inline 4 cylinder, turbocharged engine that employs advanced modular design principles.

The engine features a split cooling system. The system contains a Powertrain Control Module (PCM) controlled electric thermostat and a fully variable coolant pump. The variable coolant pump enables engine coolant to remain static in the engine to maximize heat transfer during warm up. When engine coolant flow is required for engine cooling, the minimum flow is provided by the variable coolant pump.

The split cooling electric thermostat housing limits coolant flow in the cylinder block while allowing engine coolant to circulate through cross flow channels in the cylinder head. Parasitic losses are also optimized when the variable coolant pump is delivering reduced flow.

An electronically controlled variable flow oil pump with integral vacuum pump matches its flow rate according to engine speed, load and temperature. Oil flow to the piston cooling oil jets is solenoid controlled and operates only when needed.

The 2 camshafts incorporate the Variable Camshaft Timing (VCT) system. The VCT system allows the timing of the intake and exhaust valves to be adjusted independently of each other. The VCT system is controlled by the PCM using information from the Camshaft Position Sensor (CMP).

Beside the VCT there is a Continuously Variable Valve Lift (CVVL) system that can adjust the intake valve timing and maximum lift. The CVVL system allows the engine to always operate at optimal efficiency. The CVVL system reduces fuel consumption and increases power and torque in the lower speed range. The CVVL system is controlled by the PCM.

The engine uses a Bosch High Pressure (HP) Direct Injection (DI) fuel system. The fuel pressure is provided by a HP fuel pump which is driven from the exhaust camshaft. The HP fuel pump supplies the fuel rail, and then the fuel rail supplies the 4 fuel injectors with fuel at a controlled pressure.

There are many dynamic and static seals on the engine. All seals and gaskets shall be considered single use and if they are removed shall be replaced.

Various engine systems are located on the engine assembly and driven directly and indirectly by the engine operation.

Refer to the relevant section for further information:

- Engine cooling

- Fuel system

- Air intake system

- Engine emission control

- Accessory drive

- Starting system

- Turbocharger

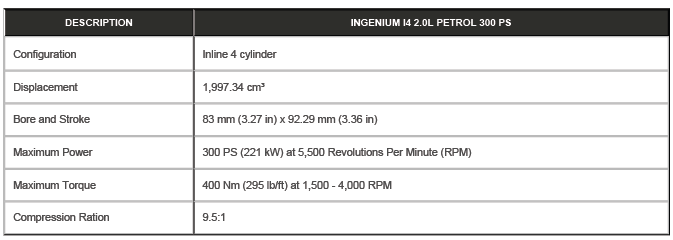

Technical Specifications